How Long Will it Take

Custom Made Rings With Custom Tailored Timelines

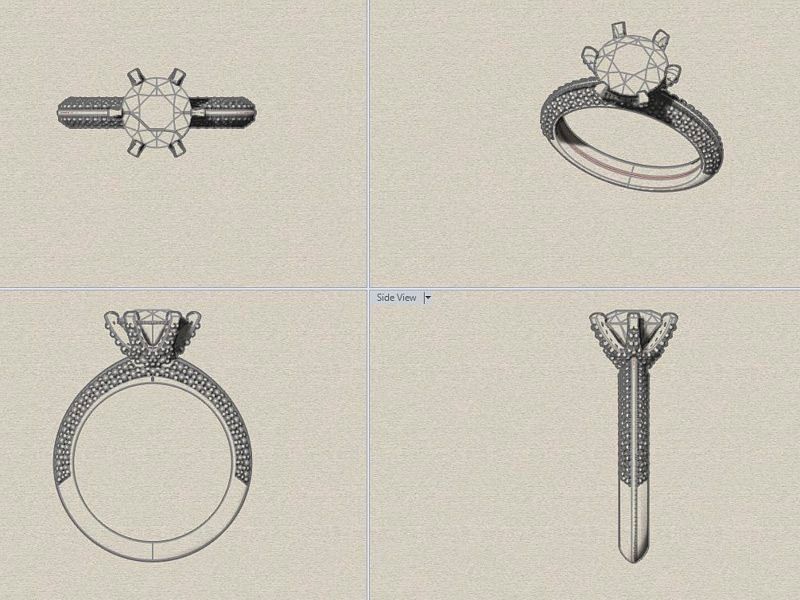

Our manufacturing time varies depending on the complexity of the design and the workshop we use to create it. Our standard manufacturing time is 25 working days from design sign off by the client. This is when the design has been built in our engineering software and you are completely happy with every element of the design and ready for the manufacturing to commence. Getting to this stage is very much depended on yourself and the availability of stones etc, but the design process is usually complete between 2-5 working days.

We also offer an express service for an additional fee in case you require your ring sooner which is available on most of our projects.

→ Return to Top

Ring Size Guidance

The likelihood of knowing your partner’s finger size is very slim if you are purchasing an engagement ring, as most of the time this is a surprise. This isn’t a problem as we have some handy tips to help you work this out.

How to obtain the correct finger size

- Take a ring your partner currently wears and have it measured by a professional jeweller. Any jewellery retailer should be able to assist with this but please be mindful of the finger and hand this is worn on. If you do get it wrong, do not worry. as approximately 70% of our rings come back for resizing which is a complementary service Durham Rose offers.

- You could also enlist the help of your family and friends. Ask one of your partners friends to do a ‘fake’ shopping trip because they are looking to buy a new ring. Whilst they are in the jewellers having their finger measured they could also get your partner to have theirs measured.

What not to do when trying to obtain the correct finger size

- Do not rely on a piece of string to give you any sort of idea on a finger size. The material isn’t structured and will not give an accurate reading. It is important to remember the knuckle is the widest point of most peoples fingers, so the ring needs to pass over this area comfortably which string will not be able to do

- Many people use the plastic ring sizes you can buy online. If you want to use this as a guide make sure it can slide over the knuckle and do not pull it tight once its in the correct place as this will give you a false measurement

Other factors to consider when obtaining the correct finger size

- The finger size will also be affected depending on the width of the band. The average engagement ring is 2mm wide, but if the band is particularly wide it will create more of a vacuum on the finger and therefore the size may need to increase slightly so it is more comfortable to wear.

- The engagement ring usually sits on the third finger on the left hand next to your little finger. If you are right handed, your left hand tends to be a size smaller and vice versa. There are no rules to follow in guessing your partner’s finger size, but if you have bought rings previously which are worn on the right hand your design expert will be able to assist with the size of your partner’s ring finger

- If you are purchasing a ring to sit next to another ring it may be worth increasing the finger size by half a size so the ring set does not create a vacuum on the finger.

→ Return to Top

Delivery

We believe the beauty of the ring should be reflected in the beauty of its arrival

Ring Book

We love what we do. We love what we are a part of. We love going the extra mile for each and every client and we feel that such a momentous life experience should be documented from start to finish. We do this by providing you with a photobook of how you brought your dream moment from design to reality.

Lets us guide you through the journey this incredible piece of jewellery went through before it became the piece of art you presented to your loved one.

You will receive a book that features an array of images; including a picture of the proposed deign you first created along with the final renders, a 3D printed wax model picture along with several other production images. These may include a photograph of the raw casting and our highly skilled craftsmen, sat at the bench hand setting your carefully selected stones. Once the ring is finished it is inspected at the Durham Rose Head Office where we photograph the finished pieces. These images will be included in the book too. The last pages are where we include the proposal images you send us to tie the entire process together from from how the idea started to the proposal itself. The perfect finishing touch to your story.

→ Return to Top

Hallmarking and Engraving

What is Hallmarking?

Hallmarking is a legal requirement in the UK to ensure proof of authenticity. This is typically the last stage in the manufacturing process. A hallmark is made up of a series of marks presented as laser engravings the surface of the metal. It can be thought of as a unique ‘birthmark’; giving your piece of jewellery a distinguished place of origin. It guarantees that you are getting the exact purity of metal that you have purchased. The symbols of a hallmark give the following information:

- The guaranteed standard of fineness

- The Assay office at which the article was tested and marked

- The year in which the article was tested and marked

- A sponsors mark

Here at Durham Rose we send your pieces to the trusted Sheffield Assay office for certification and hallmarking. Other locations for hallmarking are in Edinburgh, London and Birmingham each represented differently in the hallmark by distinguishing symbols

The Standard Of Fineness

This relates to the quality of type of metal, for example the purity of the precious metal content. Each metal is measured in parts of 1000 i.e. 750 parts per 1000 is equivalent to the 18 carat gold standard. The metal alloy must be at least 750 parts per 1000 to be marked as 18 carat gold. If the metal were 9 carat gold the reading would have to be above 375 per 1000.

In the UK fine jewellery is usually made to the fineness of 18ct gold which is 750. The standard UK marking for silver is sterling, 925. The Platinum mark would be 950 along with Palladium

Platinum

Gold

Palladium

Silver

The Assay Office Mark

This symbol shows which assay office marked and tested the article. As you can see from the symbols below. Birmingham is represented by an anchor, Edinburgh is represented by a castle and London is represented by a leopard’s head. Here at Durham Rose we send your pieces to the trusted Sheffield Assay office for certification and hallmarking, represented by an English rose.

Year Of Hallmark

The date an article was hallmark is advertised used date letter. Examples below:

The Sponsors Mark

To have a sponsor’s mark you have to register with the assay office. This is usually the initials of the maker/designer but it could also be the manufacturer or retailer. We at Durham Rose use a ‘DR’.

Optional Traditional Mark

The traditional mark tells you which metal the piece is made of.

What is Engraving?

To add further sentiment to your piece of jewellery, you may wish to include some engraving on the inside of your band. This can be approved in a variety of fonts and we can even engrave your personal hand writing or an image. Most of our clients have a significant date or place that is completely unique to the occasion and we would be delighted in bringing this to life for you.

The majority of our engraving is laser engraved. This allows for precision is such as small area, however sometimes we need to rely on the steady hand and expertise of hand engraving, if the laser engraver can’t focus for example. Laser engraving is a quick and effective process. Using a bonding agent you can customise your piece when heat from the laser bonds with the marking agent to the metal resulting in a permanent mark which we refer to as the engraving.

→ Return to Top

Our Workshops

Locations

We are fortunate to have workshops in London, the United States and India with a superior team of experts, craftsmen and women with a wealth of knowledge and experience in the jewellery industry.

Each workshop specialises in different fortes and as a result, have varying timescales for manufacturing. We carefully select the perfect workshop to manufacture your ring.

London

Our normal manufacturing time is 4-6 weeks, but our UK based craftsmen are able to deliver in a much shorter timescale, so if you find yourself in a hurried position, please do not hesitate in contacting us. Our London based workshop is able to create stunning pieces of jewellery within a matter of days using our express delivery service.

United States

Our United States manufacturing facility has an extensive stock of beautiful gemstones and diamonds available at their fingertips. Our trained diamond experts go beyond the norm for hand selecting the perfect diamond by comparing them side by side to admire the light performance and natural beauty of the diamonds before presenting their favourite. Their combined knowledge and expertise are wonderful at creating classic ring designs.

India

If your taste runs to that of a more intricate palette, with a meticulous eye for precision, we would highly recommend our India workshop. All of our rings are handset and hand polished so it is very easy to lose the finer detailing in polishing. Our workshop pays extra attention to get this on point not to over polish and lose such important detail.

Needless to say, we are extremely proud of all the craftsmen that work for Durham Rose.

London

India

United States

→ Return to Top

AS SEEN IN